Transforming Designs: How Laser Cutting Services Redefine Manufacturing and Crafting

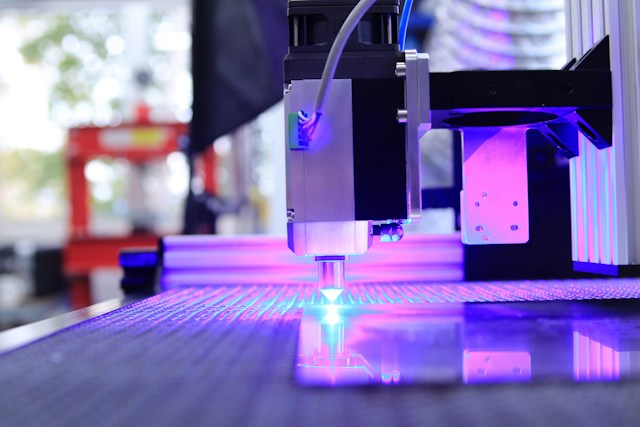

Laser cutting involves firing a focused beam of light at a material to cut, vaporize, melt, or etch it. The resulting edge is high-quality and precise, without extra machining supplies like lubricants or inks.

Everyone hands out business cards and brand swag, but it is easy to stand out with custom-branded materials. Laser cutters are the most versatile and environmentally friendly way to make these products.

Precise Cuts

When fabricating parts from metal, laser cutting is a highly precise thermal process that can save time and money on machining costs. It’s a great choice for designs that require tight tolerances or precise cutouts, such as small holes about the material’s thickness.

Another benefit of laser cutting Manitoba is the lack of waste that other fabrication processes produce. Compared to CNC machines, laser cutters create a more refined edge finish with less excess materials. This can help reduce waste and the cost of chemicals and machine supplies like lubricants.

Designers can use this to make architectural models, home decor, and other craft projects. For example, they can use laser cuts to make lampshades and wall art, as well as room dividers and decorative panels for furniture. They can also create educational models and puzzles and add decorative patterns and inlays to leather goods and woodworking projects.

Eco-Friendly

Laser cutting is a contactless process that uses a focused beam of light to slice through materials. This allows for greater precision and efficiency compared to traditional machine tools, resulting in less waste material being created in manufacturing. It also eliminates the need for lubricants and other chemicals like inks (if the laser cutter is used to engrave).

Additionally, the durability of laser cutting machines means they can often be utilized for longer periods than traditional equipment. This is particularly important in the case of large production runs, as it helps to reduce energy consumption and potential waste material.

Many industries in Manitoba use laser-cutting technology to help them reduce the cost of their products and tap new potential. For example, fabric laser cutters can create textile and padding patterns that can be incorporated into furniture designs without extra expense. The same applies to other materials, such as metals. These technologies allow manufacturers to create prototypes of new products quickly and accurately while reducing costs simultaneously.

Versatility

Laser cutting is a versatile technology that can be used for various applications. This includes machining, engraving, and cutting. It is also able to cut a variety of materials, including metal. This versatility makes it an ideal option for a variety of different industries.

Unlike traditional manufacturing processes, laser cutting is a non-contact process. This means there is no need to change dies, reducing the cost of production. This is especially beneficial for smaller runs and prototypes.

In addition to this, laser cutting is also fast. This helps reduce turnaround time and leads to a reduction in waste material. This is particularly helpful for businesses that need to meet tight deadlines.

In addition, laser cutting is a safe and clean process. This is particularly important for medical and healthcare companies, as it allows them to produce stents and heart valves. This reduces the risk of infection and improves patient outcomes.

Customization

When you want to create a unique piece, laser cutting services can provide customized designs that fit your needs. You can add your text or graphics to the design, which will be cut out of the material of your choice.

The laser cutting process uses a computer to direct the beam of light at the material to be cut. This light melts, burns, or vaporizes the fabric for a clean, high-quality edge.

For example, architects can use a laser cutter to create scale models of buildings or landscapes. Home decorators can add a unique touch to their rooms by adding custom laser-cut lampshades or wall art. Crafters can create one-of-a-kind trellises, gates, or pinwheels for their gardens. Cake decorators can offer customers a unique choo-choo train or racecar for their children’s birthday cakes.